Wood pellets, a sustainable and increasingly popular biofuel, are categorized into different grades based on their quality and intended use. Industrial wood pellet grades, specifically those designated as I1, I2, and I3, are designed for large-scale energy generation and industrial processes.

Let’s delve into the specifications and applications of these grades with Farmvina today!

Decoding the Standards

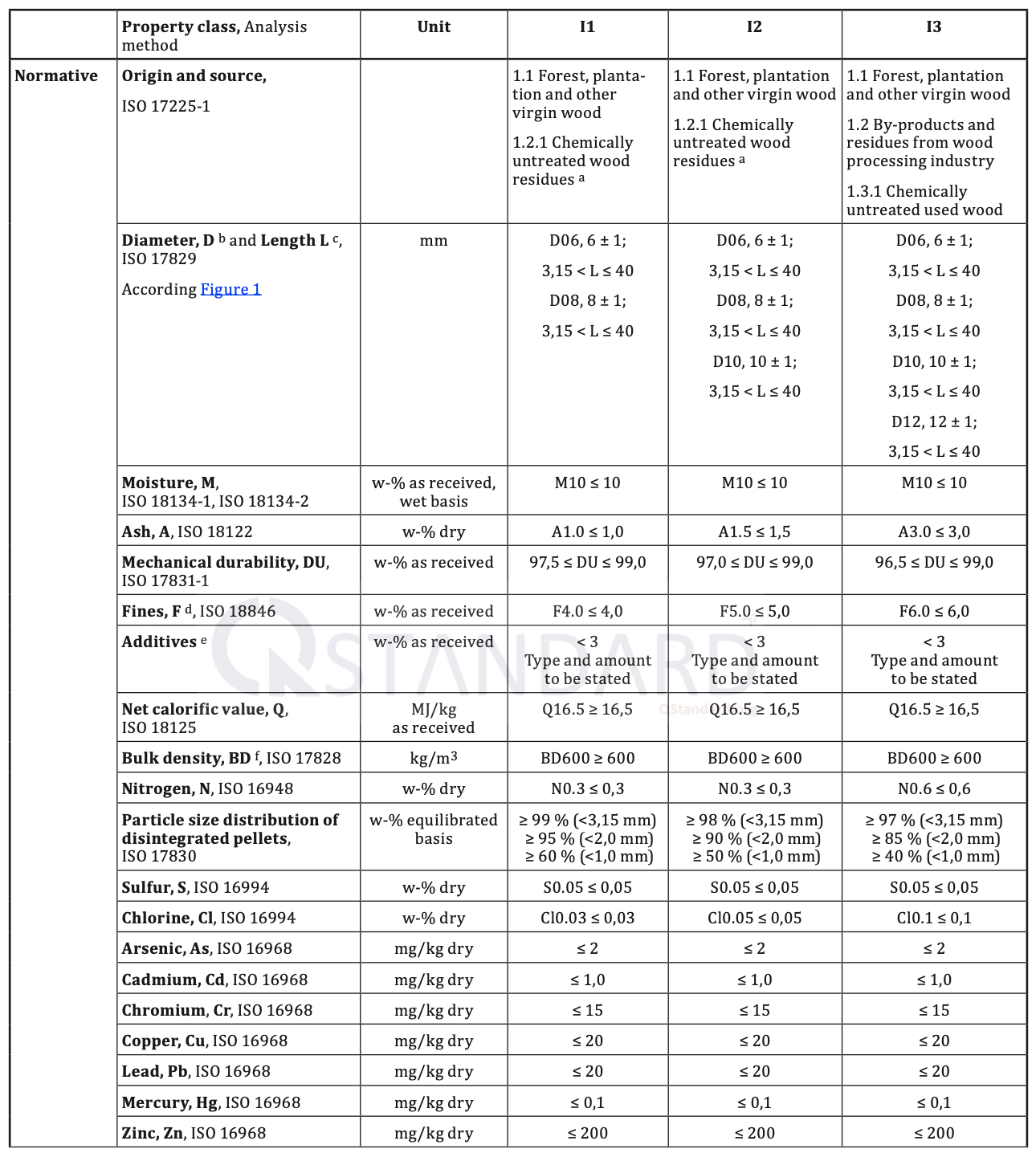

International standards, such as the ISO 17225-2, define the parameters for classifying wood pellets. Here’s what you need to know about the I1, I2, and I3 grades:

I1: The Premium Grade

- Origin: Primarily made from stem wood, chemically untreated wood residues, and whole trees without roots. It might also include logging residues and bark.

- Properties: I1 pellets boast the lowest ash content (below 0.7%) and strictest limits on nitrogen and chlorine content. Their high calorific value and low pollutants make them optimal for power plants with stringent emission regulations.

I2: The Versatile Grade

- Origin: A broader range of sources is permitted for I2 pellets, including those used for I1 grade, forest residues, and chemically untreated used wood.

- Properties: Offers a balance between quality and practicality. Ash content is slightly higher (below 1.5%), but still manageable for most industrial boilers.

I3: The Practical Grade

- Origin: The most diverse sourcing, including all materials permitted for I1 and I2, and possibly higher percentages of bark.

- Properties: I3 pellets have the highest ash content tolerance (below 3%), making them suitable for industrial applications where ash handling is less of a concern.

Applications of Industrial Pellets

Industrial wood pellets find use in various sectors:

- Power Generation: I1 and I2 grades are commonly used in power plants, either exclusively or co-fired with coal to reduce carbon emissions.

- Industrial Heating: Boilers in various industries can be fueled by industrial wood pellets, providing process heat for manufacturing, drying, and other applications.

- Combined Heat and Power (CHP): Some facilities utilize industrial pellets in CHP plants, generating both electricity and heat for increased efficiency.

Factors Influencing Grade Selection

The optimal industrial wood pellet grade for a specific application depends on:

- Boiler/Furnace Specifications: The equipment’s tolerances for ash content and fuel quality dictate the suitable pellet grade.

- Emissions Regulations: Stricter environmental regulations often necessitate using I1 or I2 pellets.

- Cost Considerations: I1 pellets are generally more expensive, while I3 offers a more economical option when ash handling isn’t as critical.

- Availability: Local sourcing and market conditions can impact the availability and price of different pellet grades.

In Conclusion

Understanding the distinctions between I1, I2, and I3 industrial wood pellet grades is crucial for making informed choices in large-scale energy generation and industrial processes. By carefully considering your specific requirements, you can ensure optimal fuel performance, cost efficiency, and compliance with environmental regulations.

Originally posted 2024-04-01 14:52:40.