The future of Vietnamese pellets lies in technological innovations such as advanced processing methods and sustainable sourcing practices to enhance quality and environmental sustainability.

Revolutionizing the Pellet Industry: The Top Tech Innovations in Vietnamese Pellets

The pellet industry in Vietnam has been experiencing significant growth in recent years. Pellets, which are small cylindrical pieces of compressed biomass or wood, are used as a renewable energy source and as a substitute for fossil fuels. The demand for pellets in Vietnam is driven by several factors, including the country’s increasing energy needs, the government’s push for renewable energy sources, and the availability of biomass resources.

Vietnam’s rapid economic growth has led to a surge in energy consumption. As the country continues to develop and industrialize, the demand for electricity is expected to increase significantly. To meet this growing demand, Vietnam is looking to diversify its energy sources and reduce its reliance on fossil fuels. Biomass pellets offer a sustainable and environmentally friendly alternative, as they are made from agricultural waste, forestry residues, and other biomass materials.

The Vietnamese government has also been actively promoting renewable energy sources as part of its efforts to reduce greenhouse gas emissions and combat climate change. In 2015, the government set a target of increasing the share of renewable energy in the country’s total energy consumption to 10% by 2030. This has led to increased investments in biomass power plants and pellet production facilities.

Furthermore, Vietnam has abundant biomass resources, including rice husks, bagasse, wood chips, and sawdust. These resources are readily available and can be used as feedstock for pellet production. The availability of biomass resources combined with the government’s support for renewable energy has created a favorable environment for the growth of the pellet industry in Vietnam.

The Role of Technology in Revolutionizing the Pellet Industry

Technology has played a crucial role in revolutionizing the pellet industry in Vietnam. It has transformed the way pellets are produced and consumed, leading to improved efficiency, quality control, and customization options. The adoption of technology in the pellet industry has also resulted in cost savings and reduced environmental impact.

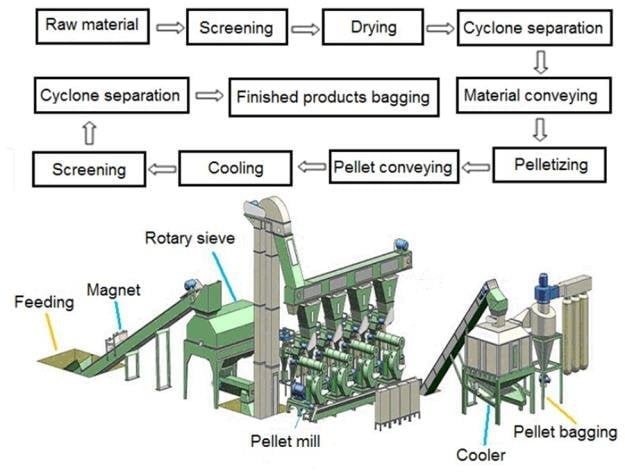

One of the key technological advancements in the pellet industry is automation. Automated pellet production systems have streamlined the manufacturing process, reducing labor costs and improving efficiency. These systems can handle various tasks, such as raw material handling, grinding, drying, pelletizing, and packaging. By automating these processes, pellet manufacturers can increase production capacity and reduce the risk of human error.

Robotics is another technology that has revolutionized the pellet industry. Robotic systems are used in pellet manufacturing to enhance quality control and improve efficiency. These systems can perform tasks such as sorting and inspecting pellets for defects, ensuring consistent quality and reducing waste. Robotics also enable faster production cycles and higher throughput, leading to increased productivity.

The Internet of Things (IoT) has also had a significant impact on the pellet industry. IoT-enabled pellet production systems allow real-time monitoring and optimization of the manufacturing process. Sensors and connected devices collect data on various parameters, such as temperature, moisture content, and energy consumption. This data is then analyzed to identify inefficiencies and optimize production parameters, resulting in improved product quality and reduced energy consumption.

Automation: Streamlining the Pellet Production Process

Automation has revolutionized the pellet production process by streamlining operations and reducing costs. Automated pellet production systems can handle various tasks, from raw material handling to packaging, with minimal human intervention. This not only improves efficiency but also reduces labor costs.

One example of an automated pellet production system is a fully automated pellet mill. These mills are equipped with sensors and control systems that monitor and adjust various parameters, such as moisture content, temperature, and pressure. The system can automatically adjust these parameters to ensure optimal pellet quality and production efficiency.

Another example is an automated packaging system. These systems can automatically weigh, bag, and seal pellets, eliminating the need for manual labor. They can also print labels and track inventory levels, making it easier for manufacturers to manage their production and distribution processes.

Automation in the pellet industry has several benefits. It improves efficiency by reducing the risk of human error and increasing production capacity. It also reduces labor costs, as fewer workers are needed to operate and monitor the production process. Additionally, automation improves product quality and consistency by ensuring that production parameters are consistently met.

Robotics: Enhancing Quality Control and Efficiency in Pellet Manufacturing

Robotics has revolutionized the pellet industry by enhancing quality control and improving efficiency in manufacturing. Robotic systems can perform tasks such as sorting and inspecting pellets for defects, ensuring consistent quality and reducing waste. They can also handle repetitive tasks with speed and precision, leading to increased productivity.

One example of a robotic system used in pellet manufacturing is a robotic sorting system. This system uses cameras and sensors to identify and remove pellets that do not meet quality standards. It can detect defects such as cracks, chips, or irregular shapes, ensuring that only high-quality pellets are packaged and distributed.

Another example is a robotic palletizing system. This system can automatically stack bags or containers of pellets onto pallets, eliminating the need for manual labor. It can also optimize the stacking pattern to maximize the use of space on the pallet, reducing transportation costs.

Robotics in the pellet industry offers several benefits. It improves quality control by ensuring that only high-quality pellets are produced and distributed. It also increases efficiency by automating repetitive tasks and reducing the risk of human error. Additionally, robotics enables faster production cycles and higher throughput, leading to increased productivity.

IoT: Monitoring and Optimizing Pellet Production in Real-Time

The Internet of Things (IoT) has revolutionized the pellet industry by enabling real-time monitoring and optimization of pellet production. IoT-enabled pellet production systems use sensors and connected devices to collect data on various parameters, such as temperature, moisture content, and energy consumption. This data is then analyzed to identify inefficiencies and optimize production parameters, resulting in improved product quality and reduced energy consumption.

One example of an IoT-enabled pellet production system is a smart dryer. This system uses sensors to monitor the moisture content of the pellets during the drying process. The data collected by the sensors is transmitted to a central control system, which adjusts the drying parameters in real-time to ensure optimal moisture levels. This not only improves product quality but also reduces energy consumption by minimizing over-drying.

Another example is a smart pellet mill. This mill is equipped with sensors that monitor various parameters, such as temperature, pressure, and pellet density. The data collected by the sensors is analyzed to identify inefficiencies and optimize production parameters. For example, if the temperature is too high, the system can automatically adjust the cooling process to prevent overheating and improve pellet quality.

IoT in the pellet industry offers several benefits. It enables real-time monitoring and optimization of production parameters, leading to improved product quality and reduced energy consumption. It also allows manufacturers to remotely monitor and control their production processes, increasing operational efficiency and reducing downtime.

Big Data Analytics: Improving Decision-Making in the Pellet Industry

Big data analytics has revolutionized the pellet industry by improving decision-making for manufacturers. By analyzing large volumes of data collected from various sources, such as sensors, machines, and weather stations, pellet manufacturers can gain valuable insights into their production processes and make informed decisions.

One example of big data analytics in the pellet industry is predictive maintenance. By analyzing data on machine performance and maintenance history, manufacturers can predict when a machine is likely to fail and schedule maintenance proactively. This reduces downtime and improves operational efficiency.

Another example is demand forecasting. By analyzing historical sales data, market trends, and other relevant factors, manufacturers can predict future demand for pellets with greater accuracy. This allows them to optimize their production schedules and inventory levels, reducing costs and improving customer satisfaction.

Big data analytics in the pellet industry offers several benefits. It improves decision-making by providing manufacturers with valuable insights into their production processes and market trends. It also enables predictive maintenance, reducing downtime and improving operational efficiency. Additionally, big data analytics allows manufacturers to optimize their production schedules and inventory levels, reducing costs and improving customer satisfaction.

Artificial Intelligence: Enabling Predictive Maintenance and Quality Assurance

Artificial Intelligence (AI) has revolutionized the pellet industry by enabling predictive maintenance and quality assurance. AI algorithms can analyze large volumes of data collected from various sources, such as sensors, machines, and weather stations, to identify patterns and make predictions. This allows manufacturers to proactively schedule maintenance and ensure consistent product quality.

One example of AI-enabled pellet production systems is predictive maintenance. By analyzing data on machine performance, maintenance history, and other relevant factors, AI algorithms can predict when a machine is likely to fail and schedule maintenance proactively. This reduces downtime and improves operational efficiency.

Another example is quality assurance. AI algorithms can analyze data on pellet characteristics, such as size, density, and moisture content, to identify patterns and detect defects. This allows manufacturers to ensure consistent product quality and reduce waste.

AI in the pellet industry offers several benefits. It enables predictive maintenance, reducing downtime and improving operational efficiency. It also enhances quality assurance by ensuring consistent product quality and reducing waste. Additionally, AI algorithms can optimize production parameters to improve product quality and reduce energy consumption.

3D Printing: Advancing Pellet Production and Customization

3D printing has revolutionized the pellet industry by advancing pellet production and customization. 3D printing technology allows manufacturers to create complex shapes and structures with precision, opening up new possibilities for pellet design and customization.

One example of 3D printing in the pellet industry is the production of custom-shaped pellets. By using 3D printing technology, manufacturers can create pellets with specific shapes and sizes to meet the requirements of different applications. This allows for greater flexibility and customization in pellet production.

Another example is the production of multi-layered pellets. 3D printing technology allows manufacturers to create pellets with multiple layers, each with different properties or compositions. This opens up new possibilities for the development of advanced materials and applications.

3D printing in the pellet industry offers several benefits. It allows for greater flexibility and customization in pellet production, enabling manufacturers to meet the specific requirements of different applications. It also opens up new possibilities for the development of advanced materials and applications. Additionally, 3D printing technology can reduce waste by optimizing material usage and minimizing the need for post-processing.

Renewable Energy: Harnessing Biomass Pellets for Sustainable Power Generation

Biomass pellets are being used for sustainable power generation in Vietnam and other countries. Biomass power plants use biomass pellets as fuel to generate electricity, providing a renewable and environmentally friendly alternative to fossil fuels.

One example of a biomass pellet power plant in Vietnam is the Dinh Vu Biomass Power Plant. This power plant, located in Hai Phong City, uses rice husk pellets as fuel to generate electricity. The plant has a capacity of 11 MW and supplies electricity to the national grid.

Another example is the Long An Biomass Power Plant. This power plant, located in Long An Province, uses bagasse pellets as fuel to generate electricity. The plant has a capacity of 30 MW and supplies electricity to the local grid.

Biomass pellet power plants offer several benefits. They provide a renewable and environmentally friendly alternative to fossil fuels, reducing greenhouse gas emissions and combating climate change. They also contribute to rural development by creating jobs and stimulating economic growth in rural areas.

Blockchain: Securing the Supply Chain of Vietnamese Pellets

Blockchain technology is revolutionizing the pellet industry by improving the transparency and security of the pellet supply chain in Vietnam. Blockchain is a decentralized and transparent ledger that records transactions in a secure and immutable manner. It allows for the secure and transparent tracking of pellets from production to consumption, ensuring the integrity of the supply chain.

One example of blockchain in the pellet industry is the use of smart contracts. Smart contracts are self-executing contracts with the terms of the agreement directly written into code. They automatically execute transactions and enforce the terms of the agreement, eliminating the need for intermediaries and reducing the risk of fraud.

Another example is the use of blockchain to track and verify the origin of pellets. By recording information about the production process, such as the source of biomass materials, manufacturing parameters, and quality control measures, on a blockchain, manufacturers can provide proof of origin and ensure product traceability.

Blockchain in the pellet industry offers several benefits. It improves transparency and security by providing a decentralized and immutable record of transactions. It also reduces the risk of fraud by eliminating intermediaries and ensuring the integrity of the supply chain. Additionally, blockchain enables greater trust and accountability among stakeholders in the pellet industry.

The Future of Pellet Industry in Vietnam and Beyond

The pellet industry in Vietnam is experiencing significant growth, driven by increasing energy needs, government support for renewable energy, and abundant biomass resources. Technology has played a crucial role in revolutionizing the pellet industry, enabling automation, robotics, IoT, big data analytics, AI, 3D printing, and blockchain.

Automation has streamlined the pellet production process, reducing costs and improving efficiency. Robotics has enhanced quality control and efficiency in manufacturing. IoT has enabled real-time monitoring and optimization of pellet production. Big data analytics has improved decision-making for manufacturers. AI has enabled predictive maintenance and quality assurance. 3D printing has advanced pellet production and customization. And blockchain has secured the supply chain of Vietnamese pellets.

The future outlook for the pellet industry in Vietnam and other countries is promising. As the demand for renewable energy continues to grow, the pellet industry is expected to expand further. Technology will continue to play a crucial role in driving this growth, enabling further advancements in automation, robotics, IoT, big data analytics, AI, 3D printing, and blockchain. With these technological advancements, the pellet industry will continue to contribute to sustainable power generation and environmental conservation.

Originally posted 2024-04-25 10:30:21.

It’s very bright indeed! I was in Vietnam last year to seek for investment opportunities. Perhaps the wood pellet is something that I am looking for.

Hi Farmvina! We may want to explore an opportunity to invest in a medium-sized wood pellet factory in Quy Nhon (Vietnam). How best could I reach you for more details?

@Coralee: Hello, you may reach us by dropping an email to admin@farmvina.com. Your plan is exciting and aligned with our future direction, so we do hope to talk soon.